Assembly Solutions

Our assembly solutions are designed to meet the needs of companies operating in highly competitive markets, facing increasing cost pressures, and struggling with ever-shorter lead times for new products.

In many cases, the assembly system must be designed and built in parallel with the final design of the new product.

With the demand for higher standards, lower volumes and shorter product lifecycles, the requirements for automation systems have become more complex.

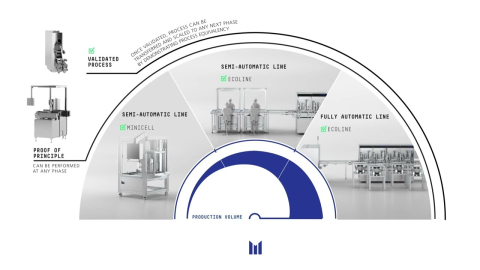

Assembly solutions must be cost-effectively scalable from development to medium- or fully-automated high-volume production to stay ahead of the curve.

Automated platforms and customized processes are essential components of these solutions to ensure maximum efficiency and productivity in your manufacturing processes.