Unequaled

Expertise in

Pen injector assembly.

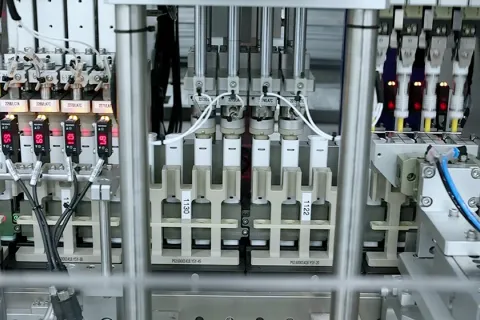

Mikron Automation is an innovator in manufacturing systems for the pre- and final assembly of pen injectors. For decades, we have collaborated with the world's leading pharmaceutical and medical device companies, mastering all processes to deliver precision-engineered assembly solutions for pen injectors. Our state-of-the-art Pen Injector assembly lines are designed to handle up to 550 parts per minute, ensuring unparalleled efficiency and reliability.

From modular designs to scalable systems, we tailor each solution to meet your unique project requirements while preparing for future needs. Our expertise includes hot foil marking, glass cartridge feeding and testing, grease spotting, priming, labeling, multiple force and torque testing, vision-based quality inspection, and 100% mechanical functional testing.

Whether you’re producing small batches for regulatory submissions or ramping up for full-scale production, our Mikron MAIA assembly platform ensures consistent and repeatable processes. Our Pre-Production services provide end-to-end support, including design for manufacturing/assembly (DFM/DFA), process development, Proof of Principle and small-batch cleanroom assembly, all compliant with FDA, GMP, and GAMP 5 standards.

With a global presence and a proven track record, Mikron Automation is your partner in achieving excellence in a pen injector assembly line. Join us and be part of a team that drives innovation and excellence in medical device assembly.

Device examples

Complex process expertise

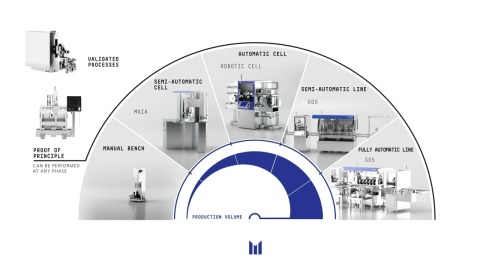

From low to high volume

- Hot foil marking

- Glass cartridge feeding and check

- Grease spotting

- Priming and multiple force and torque tests

- Labelling

- Quality inspection by vision

- 100% mechanical functional test

Videos shown are examples and respect our organization’s core value of confidentiality. They do not represent the full scope of our expertise. For additional information, please contact us.

Scalable Assembly Solutions

Complex process expertise from low to high volume production

Mikron’s scalable solutions are the result of decades of experience in the design and manufacture of high-performance assembly systems.

Pre-Production Services

Cutting edge services for accelerated market launch

We offer a full suite of services, developed to help medical device manufacturers de-risk their programs and accelerate through the manufacturing design phase.

Advise

Supporting the development of robust design that can reliably be assembled.

Helping you design a product that is ready for successful design transfer.

Characterize

Developing process characterization to ensure your product is ready for manufacturing.

Identifying critical processes at an early stage and optimizing your manufacturing processes step by step.

Validate

Executing the qualification protocols and delivering all documents for validation requirements.

Helping generate your equipment’s validation package.

Articles and white papers

Read more

Pharma / Medtech

Pharmaceutical and Medical devices assembly solutions