Scalable assembly solutions

fully integrated and truly global

With the demand for more stringent standards, greater variety, smaller volumes and ever-shorter product lifecycles, the requirements for automation solutions have risen sharply in manufacturing industries.

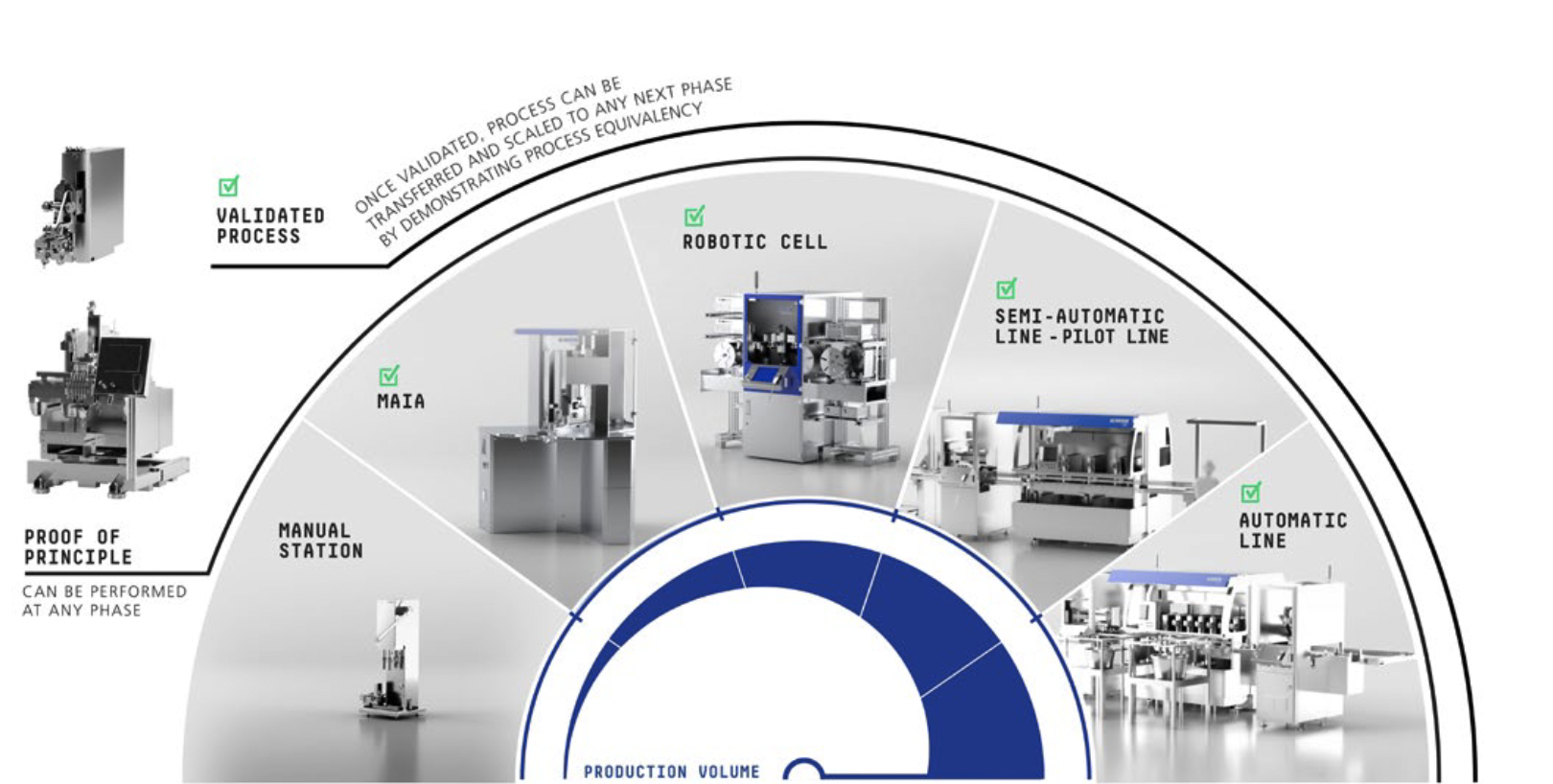

Here, Rolf Rihs, President, and Jean-François Bauer, Head of Marketing & Business Development, both of Mikron Automation, look at how – to meet customer needs – Mikron has specialised in flexible, modular assembly solutions that are easy to evolve during the different stages of a product lifecycle: from the development phase through to fully automated, maximumperformance production.

Demands on manufacturers in industries such as medical, pharmaceutical, automotive, consumer goods and electronics are especially high. In an extremely competitive market, pressure on costs is rising and the lead time for new products is getting ever shorter. An assembly solution often has to be ready before all the details of the new product are even known. In many cases, assembly solutions also need to be frequently switched to another variant.

It’s no wonder then that demand for innovative, cost-optimised solutions has risen dramatically over the past few years. The future belongs to flexible automation systems that can be expanded and enhanced easily and cost effectively – from the development phase through to fully automatic production.